TRANSPORTING AN SPM CALM BUOY FROM DUBAI TO COLOMBIA

Trusted Expertise in Complex Logistics

UTC Overseas brings decades of proven expertise in the oil and gas sector, specializing in the transport of oversized, overweight, and high-value equipment essential to offshore rigs and related infrastructure. When a client approached UTC to assist with their latest project, they had full confidence in UTC’s ability to manage complex logistics operations and ensure timely delivery.

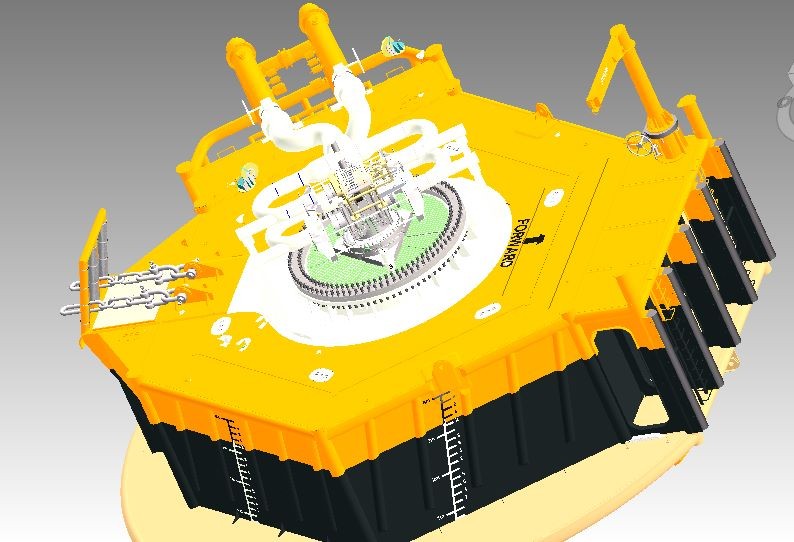

UTC successfully transported a newly fabricated Single Point Mooring (SPM) CALM Buoy from Dubai to the Port of Santa Marta, Colombia. The buoy will function as the offshore mooring and crude oil offloading interface, playing a key role in strengthening Colombia's offshore oil and gas infrastructure.

Oversized Cargo

The shipment consisted of a 322-metric-ton SPM CALM Buoy, measuring 15.61 meters in length, 16.90 meters in width, and 14.24 meters in height. Due to its over-dimensional size and heavy-lift characteristics, the buoy was transported as breakbulk cargo. Accompanying the main unit was a 20-foot container carrying spare parts and installation tools.

Both cargo units were loaded in Dubai and transported aboard a breakbulk vessel bound for the Port of Santa Marta on Colombia's Caribbean coast.

Planning For This Complex Operation

Specialized equipment and engineering support were essential to execute this non-routine, complex heavy-lift operation. The SPM buoy was lifted using a DD2000 Sheer Leg Floating Crane, rated for a safe working load of 2,000 metric tons. Custom-engineered rigging solutions were employed, including purpose-built spreader beams, stoppers, and a prefabricated grillage system designed to secure the buoy during lifting and sea transport.

Comprehensive planning and engineering studies were conducted prior to transport. Critical tasks included detailed rigging and grillage design validation, vessel stability calculations, and development of a step-by-step method statement. Technical analyses covered structural member forces, support reactions, and displacement modes for multiple load cases, including code checks for girders and evaluation of span displacement ratios.

Site visits were conducted at the fabrication yard by UTC and its partners to ensure operational readiness. Before the lifting operation involving the DD2000, comprehensive risk assessments were completed. This included pre-inspection of the designated lifting and lowering zones. These assessments covered all aspects of loading, securing, and lashing, and were reviewed by the appointed Marine Warranty Surveyor (MWS) overseeing activities at both origin and destination points.

The buoy was loaded onto the vessel and secured for ocean transport following strict safety and engineering protocols. Upon arrival at the discharge port in Santa Marta, the buoy was floated off directly from the vessel into the water, so the unit was ready for deployment. This float-off operation required controlled removal of the grillage system and precise underwater rigging installations to enable safe and efficient handling.

Managing the Project

UTC’s Ignacio Benedetti recounts the planning process. “Throughout the project, UTC was responsible for a wide range of critical logistics and marine services. This included vessel nomination and chartering, coordination of marine engineering and surveyor approvals, export customs clearance at origin, and full oversight of destination float-off operations. UTC's team also led the development and validation of risk assessments, route surveys, method statements, rigging plans, export documentation, and local agent management. UTC’s project managers ensured seamless coordination across all stakeholders, maintaining clear communications and continuity of execution to prevent any disruptions.”

Meeting Challenges Head-On

UTC’s Colombia office, serving as project sponsor, was supported by Juha Karmanto from UTC's Chartering Team and Asian Tiger, the nominated agent in Dubai. The team successfully navigated several operational challenges throughout the execution phase:

- Lifting Gear Coordination: The overhang of the buoy’s top ring required careful planning, including preparation of detailed top-view drawings and spreader bar compatibility assessments to ensure safe and balanced lifting.

- No-Weld PolicyCompliance: Due to ABS certification restrictions, a no-weld policy was enforced. To work around this stipulation, bolted connections and a prefabricated grillage system were implemented without making permanent modifications to the buoy.

- Berth Access Constraints: Limited berth availability at the fabrication yard necessitated early coordination with port authorities and timely completion of induction procedures for all personnel.

- Demurrage Risk Management: With port congestion posing a risk of demurrage charges, UTC mitigated delays through proactive berthing arrangements and advanced cargo readiness planning.

UTC Delivers

As part of a larger offshore marine terminal system, the buoy will be used for mooring tankers and transferring crude oil to and from shore through subsea pipelines, allowing operations to take place without the need for vessels to enter the port.

This project showcases UTC’s expertise in heavy-lift and marine logistics and reinforces the important role of integrated engineering, streamlined communications, and expert planning in the successful execution of complex global transport projects.