UTC sets new standard for ro-ro charters

UTC Sets New Standard with Massive Ro-Ro Charter

UTC recently transported a full charter of material handling machines for long-time customer and trusted partner, Sennebogen.

UTC's Heavy Equipment Division coordinated the transport of 81 Sennebogen cranes on the Leo Leader, a chartered ro-ro vessel, from Bremerhaven, Germany to Charleston, South Carolina, setting a new standard for complexity and scale.

For 18 years, UTC has been transporting Sennebogen’s cargo to North America, building on their long-standing relationship based on trust, honesty, and confidence in each other’s abilities. UTC devised this ambitious chartering plan to safely move a large volume of equipment while being economically sound.

Departure from Bremerhaven

The journey began in Bremerhaven, Germany, as the Leo Leader set sail with unique cargo – the main deck completely filled with 81 Sennebogen material handling machines. UTC’s established relationships with shipping lines played a pivotal role in securing the necessary Ro-Ro space, a coveted commodity in an industry experiencing record movements of cranes and agriculture equipment.

The massive undertaking required meticulous planning and coordination to ensure the sheer size and weight of the shipment could be transported and loaded safely. Multiple staging areas were set up dockside and positioned at the ready to complete the loading in one day.

Challenges & Triumphs

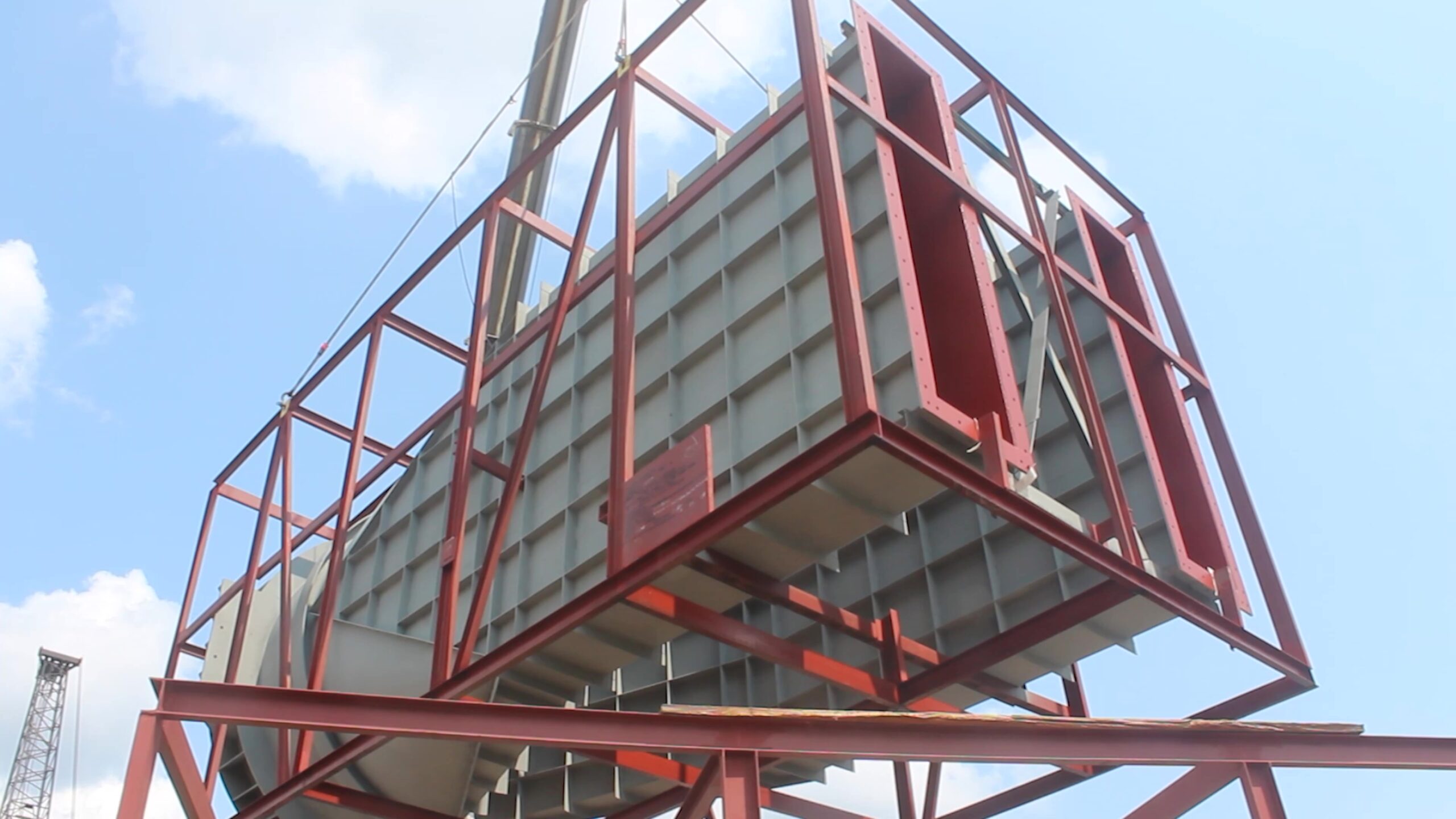

The magnitude of the operation was enormous, with approximately 10,000 freight tons of machinery requiring precise loading so each piece could drive on and subsequently and efficiently drive off at the final destination.

Over 80 trucks transported the equipment to the port, a process that took time to plan due to the necessity of obtaining permits and setting up staging areas. Permitting in Germany is complex and lengthy, but the UTC Bremen office has longstanding relationships with truckers and the port allowing them to expedite the process.

Loading intricacies

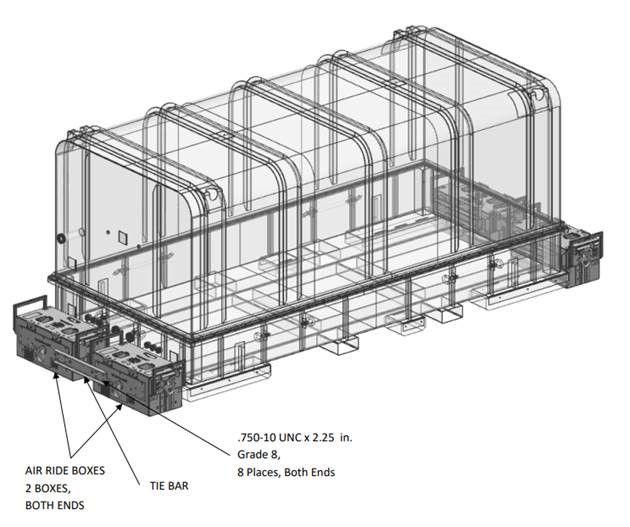

Patrik Meyer, UTC Manager – Heavy Equipment Development, who was on-site and directing the operation, recounts, “The loading process presented unique challenges, with every piece of machinery requiring specific positioning on the vessel. UTC has moved volumes of Sennebogen machines over the years and was familiar with each model, aiding in the proper placement of the valuable cargo. Blueprints were sent ahead of time, allowing for exact planning to ensure each unit could maneuver moving on and off the vessel, always considering the safety of the crew and equipment.”

Units were carefully placed within inches of each other to guarantee everything fit in their tight, preassigned location. In addition to the efficient use of space, the cargo’s precise weight and size were crucial for proper balancing of the vessel.

Charter complexities

The Leo Leader faced unexpected delays when it encountered a storm and two hurricanes, highlighting the complexities of managing transportation in the face of unpredictable weather.

In addition, the cargo’s final destination changed after the paperwork was complete. This necessitated swiftly revising documents for 81 pieces of equipment to clear customs.

Unloading in Charleston

UTC’s team scoped out the port before the vessel arrived in Charleston. This familiarity with the port’s setup and operations resulted in a solid, risk-free plan for discharge that led to a targeted, smooth process. The Sennebogen cargo, consisting of 79 assembled units, two unassembled units, and static cargo, was efficiently unloaded within the strict deadline.

The unloading began at 7:00 AM. The port actioned two to three people to unhook the cargo and two to three to drive and guide the units off the vessel. Multiple teams worked with precision in shifts that proceeded until 10:00 PM when all the cargo had safely moved to staging areas. The operation required careful coordination between port personnel, truck drivers, and UTC’s team to meet the vessel’s departure schedule.

A Flawless UTC Operation

Hans Meyer, UTC COO Heavy Equipment and Specialized Cargo, was proud of his team’s work. “The successful Ro-Ro charter of the Leo Leader stands as a testament to the expertise and dedication of UTC in tackling challenging logistical operations. The six-month planning process, attention to detail, and longstanding partnership with Sennebogen, the shipping lines, and the port all played pivotal roles in the operation’s success.”

Strong 18-year relationship

Constantino Lannes, President and CEO of Sennebogen North America, praised the seamless execution of the operation. “Chartering the Leo Leader was a tremendous task together with UTC to secure all this space and make sure we could deliver our machines to our customers when they expect them. We have worked with UTC for 18 years, and it has been tremendous cooperation. UTC takes care of the transportation of all our machines from Europe to the United States.”