UTC OVERSEAS EXECUTES COMPLEX

MARITIME TRANSPORT

Seamless Offshore Mobilization

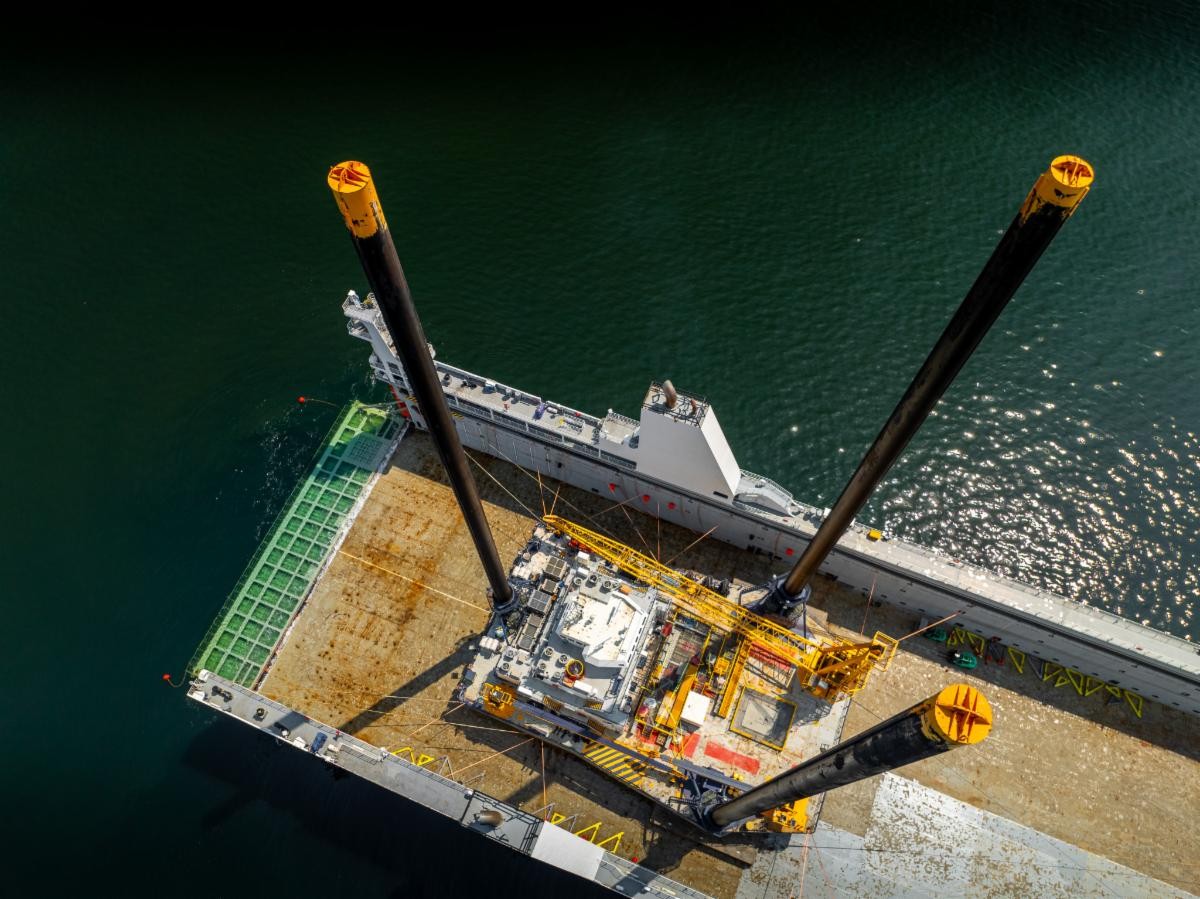

In 2024, UTC Overseas executed a challenging maritime operation—successfully mobilizing the 2,024-ton Hamad Eagle lift boat via a complex float-off from a semi-submersible heavy-lift vessel at anchorage offshore in Angola. Precision marine engineering led by UTC was on full display throughout the operation and showcased the company’s aptitude for international collaboration, safety management, and energy-sector innovation. Without the need for conventional towage or drydock reactivation, the Hamad Eagle was delivered directly into operational service, establishing a new, efficient standard in offshore mobilization.

Thinking Outside the Box

This mobilization project transported the Hamad Eagle, weighing 2,024 tons, over 6,400 nautical miles from New Orleans, USA, to Cabinda, Angola, completing the float-off and reactivation in just 72 hours, allowing immediate deployment for critical offshore decommissioning work without costly shore-based reactivation. Ocean transit took 21 days and was completed with zero incidents and full regulatory compliance across multiple jurisdictions. The customer realized over $2 million in savings by eliminating shore-based reactivation.

Project Objectives and Outcomes

| Objective | Outcome | Impact |

| Safe Float-Off | Executed without incident in 14-meter-deep water | Immediate operational deployment |

| Live Reactivation | Lift boat powered up at sea and sailed independently | Avoided costly drydock and tug assistance |

| Regulatory Compliance | Secured Angola terminal, and flag state approvals | Seamless integration into regional operations |

| Technical Excellence | Completed within a 4-hour weather window | Demonstrated advanced marine engineering |

Engineering & Technical Innovation

The float-off involved submerging the deck of the Yacht Servant by 4.6 meters using precision-controlled ballast tanks. UTC engineers employed a custom A-frame and cribbing system to maintain the Hamad Eagle’s stability and alignment during submersion. Real-time monitoring ensured safe draft separation at 2.6 meters, even in dynamic offshore conditions.

In a rare and pioneering move, the lift boat’s jacking legs were deployed sequentially while still at sea. The vessel’s onboard systems were restarted under the supervision of a marine warranty surveyor (MWS), allowing it to sail away independently to its decommissioning worksite—marking the first time this vessel class was reactivated entirely offshore.

Operational assistance was provided by the SL Africa support vessel and the Seacor Cougar work boat for precise positioning and standby support. Helicopter crew changes offered aviation logistics and engineering oversight throughout the operation. Multilingual coordination (English, Spanish, Portuguese, and French) among crews, engineers, and regulators was maintained throughout the process.

Multinational Coordination & Regulatory Excellence

This project operated efficiently through the coordination of stakeholders with multiple national and international regulatory agencies:

- Prime Contractors:

-

- UTC Overseas (USA)

- ACS Chartering Division of UTC Overseas

- Authorities Involved:

-

- U.S. Coast Guard (Departure Compliance)

- Angolan Maritime Authority (Arrival & Float-Off Oversight)

- Standards Met:

-

- ISM (International Safety Management)

- SOLAS (Safety of Life at Sea)

- MWS (Marine Warranty Survey) approvals for entire transit and float-off

- Environmental Protocols:

-

- Zero-discharge operations maintained in a sensitive marine environment

- Full adherence to offshore terminal’s compliance and protocols

Technical Firsts

The deep-water float-off was a challenging operation and the first successful activation of this vessel class in turbulent West African waters.

- First Sea-Based Reactivation: This was the first time a lift boat of this class was activated entirely offshore, without towage or dock.

- Float-Off in Angolan Waters: First heavy-lift float-off of this scale in Malongo, Angola.

- Integrated Real-Time MWS Oversight: Marine warranty survey conducted live, onboard inspections ensuring immediate compliance and performance validation.

- Offshore Wind Mobilization: This technique can be replicated for global energy offshore wind vessel mobilizations.

- Remote application: This model can be used for global energy offshore structure emplacement.

Challenging Locations: This operation provides a template for future frontier offshore regions.

Blazing New Trails

UTC pioneered a float-off procedure that bypassed traditional dockside limitations, saving millions in reactivation and tug costs. The ability to directly deliver a lift boat into service offshore, without intermediate port intervention, represents a significant breakthrough in marine project logistics. This complex operation merged diverse disciplines—naval architecture, marine engineering, aviation logistics, and regulatory compliance—into a unified, real-time effort conducted under tight environmental and safety parameters.

Beyond the technical feat, the project delivers a model for cost-effective, lower-footprint offshore mobilization in developing energy regions. It enhances uptime for critical infrastructure while reducing logistical burdens in congested ports.

UTC’s success reflects the expertise and coordination of its internal engineering team, ACS Chartering division, regional agents, vessel crews, MWS inspectors, and international regulatory partners.

Innovating for the Future

UTC Overseas’ offshore float-off and reactivation of the Hamad Eagle represents the future of heavy-lift transport in the energy sector—flexible, efficient, and globally deployable. By executing this operation with precision, safety, and innovation, UTC has not only set a new industry standard but has also laid the foundation for future offshore mobilizations in frontier regions. This project exemplifies why UTC is a leader in complex global energy transport solutions.